About PWO Offshore

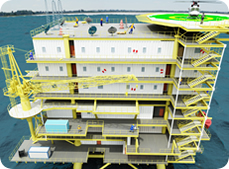

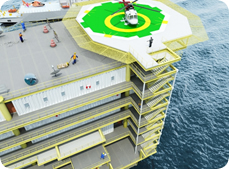

Established in 2001, PWO OFFSHORE is an indigenous full-service EPC firm providing design, detailed engineering, procurement, refurbishment and fabrication of offshore projects, especially living quarters, utility buildings and workshops. Our clients include both domestic and international energy companies. In the belief that each client is unique and has special requirements, PWO OFFSHORE brings a fresh approach to a project along with a commitment to client satisfaction.

PWO OFFSHORE understands the cultural needs and operational requirements which may impact the design of offshore facilities in West Africa. We are constantly striving to enhance our designs to embrace new technology and improved fabrication and outfitting techniques.

We believe that well designed and fabricated living quarters promote productivity, loyalty, harmony, quality, and safety on board. Our company’s measure of success is its ability to retain staff. The staff knowing that their company is committed and cares for them is essential. The type of offshore accommodation provided by a company is a measure of that commitment.

Our vision is to become the leader in the design, engineering, planning, fabrication, refurbishment and outfitting of offshore living quarters, utility buildings and workshops in Nigeria and West Africa.